About us

Savio Industrial fans&blowers designs and manufactures fans, blowers and machines intended for ventilation, air conditioning and air handling in different market sectors, ensuring high technical skills and proven experience in the different industrial applications

The main company activities, profiled according to our customers’ needs, are divided into two business units:

- The Product Division manufactures industrial axial and centrifugal fans, filters, multistage blowers, side channel blowers, air curtains, soundproof cabins, extraction towers, air handling units (AHUs) and a wide range of accessories, ensuring high technological performance, efficiency and reliability.

- The Engineering Division designs systems for filtering, conditioning and heating (HVAC Systems), ventilation in chemical and industrial processes, as well as pneumatic conveying systems and climatic wind tunnels according to customer’s specification. We are also able to manufacture axial or centrifugal fans made to customer’s specifications and side channel or multistage centrifugal blowers.

History

The quality of our company products stands out thanks to over 80 years of commitment and innovation in the manufacture of industrial and civil fans.

1945

Foundation

Savio was founded in 1945 as a company manufacturing electric motors and later shifted its focus towards new types of production.

The 1960s

Change

During the 1960s, when the founder’s sons joined the company, the product range was expanded to provide customers with new products, including industrial axial fans, centrifugal fans, blowers, multistage centrifugal blowers and equipment for dust and fine particle pneumatic conveyors. Thanks to this transition, Savio gained a leading position first in the Italian market and then in international markets.

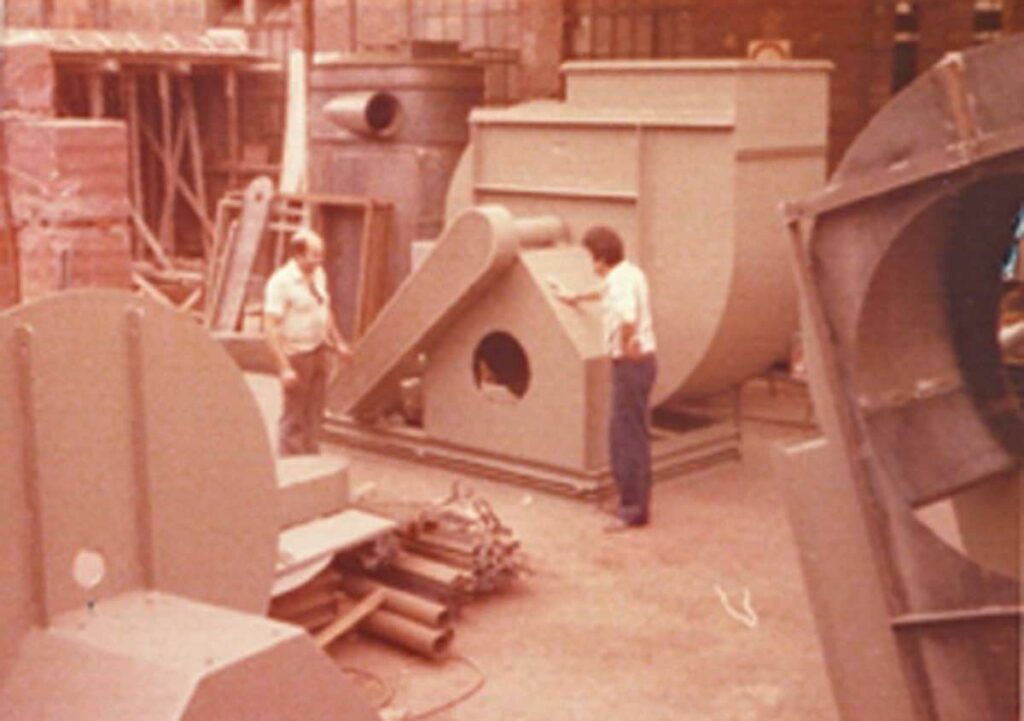

1970s and 1980s

Expansion

During the 1970s and 1980s, the company further expanded its production horizons, including the manufacturing of air handling systems complete with sections dedicated to heating, filtering, humidification and air recovery.

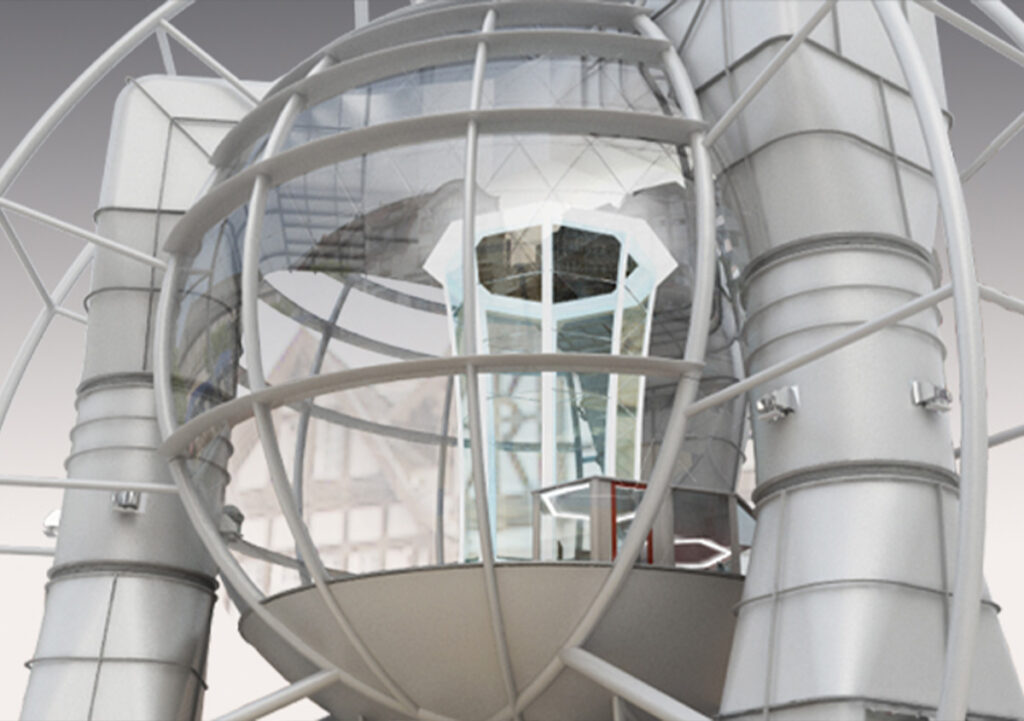

1990s

Innovation

The desire for innovation and the search for new solutions led Savio to the manufacture of the first wind tunnels, at first with air handling and recovery sections, later with the design of climatic wind tunnels capable of creating test environments at extreme temperatures.

2000s

Specialization

Market changes and investment contraction in industrial sectors, in Italy and abroad, impose new rules. Competitiveness and high-quality standards become the new company targets. Specialization is the only solution. Savio quickly adapts and positions itself in the market as a leading manufacturer of ventilation equipment (axial fans, centrifugal fans, and blowers) and air handling units (AHUs and pocket and bag filters).

2010s-2020s

Internazionalization

The need to open new markets and develop its own sales network worldwide drives Savio towards a process of company internationalization, changing both its internal and external structure and organization with significant results in Europe, Asia, and the Americas.

Today

Consolidation

Today, the company continues to operate in a single production plant, located in the hinterland of Turin, precisely in Rivoli, where it occupies an indoor production area of 7,000 square meters, and an outdoor space of 6,000 square meters for the storage of materials and semi-finished products, in addition to 900 square meters dedicated to technical and sales offices.

The third generation now runs the company and continues to invest in new machinery for continuous growth and progressive improvement.